Introduction

This bulletin reflects the opinion of the Danish Accident Investigation Board regarding the circumstances of the occurrence and its causes and consequences.

In accordance with the provisions of EU Regulation 996/2010, the Danish Air Navigation Act and pursuant to Annex 13 of the International Civil Aviation Convention, the safety investigation is of an exclusively technical and operational nature, and its objective is not the assignment of blame or liability.

The safety investigation was carried out without having necessarily used legal evidence procedures and with no other basic aim than preventing future accidents and serious incidents.

Consequently, any use of this bulletin for purposes other than preventing future accidents and serious incidents may lead to erroneous or misleading interpretations.

A reprint with source reference may be published without specific permission.

General

|

State file number: |

2024-146 |

|

UTC date: |

28-2-2024 |

|

UTC time: |

16:10 |

|

Occurrence class: |

Accident |

|

Location: |

At Tunulliarfik Fjord (60.9199 N, 45.8963 W) |

|

Injury level: |

None |

|

Aircraft registration: |

OY-HIO |

|

Aircraft make/model: |

Bell 206L-4 |

|

Current flight rules: |

Visual Flight Rules (VFR) |

|

Operation type: |

Positioning |

|

Flight phase: |

En route |

|

Aircraft category: |

Helicopter |

|

Last departure point: |

Narsarsuaq (BGBW) |

|

Planned destination: |

Qaqortoq (BGJH) |

|

Aircraft damage: |

Destroyed |

|

Engine make/model: |

1 x Rolls-Royce 250-C30P |

Synopsis

Notification

All time references in this bulletin are Coordinated Universal Time (UTC).

The Area Control Centre in Copenhagen (EKCH) notified the Aviation Unit of the Danish Accident Investigation Board (AIB) of the accident on 28-2-2024 at 17:50 hours (hrs).

The AIB notified the Danish Civil Aviation and Railway Authority (DCARA), the US National

Transportation Safety Board (NTSB), the Transport Safety Board of Canada (TSB), the European Aviation Safety Agency (EASA), and the Directorate-General for Mobility and Transport (DG MOVE) on 29-2-2024 at 20:19 hrs.

The TSB and the NTSB appointed non-travelling accredited representatives to the AIB safety investigation.

Summary

En route, the liberation of an anti-rotation tab from a thrust plate at engine bearing no. 8 resulted in a total engine power loss and, consequently, an autorotation over water.

Prior to ditching, the pilot activated the float system. However, the left hand (LH) aft float did not inflate, resulting in the helicopter rolling over onto its left side upon ditching.

The likely reason for the LH aft float not inflating was frozen water in the supply line to the LH aft float.

The accident occurred in daylight and under Visual Meteorological Conditions (VMC).

Factual information

History of flight

The flight was a VFR positioning flight from Narsarsuaq (BGBW) to Qaqortoq (BGJH).

At 15:53 hrs, the pilot departed BGBW and flew at an altitude of 1,500 feet (ft) along the Tunulliarfik Fjord towards the city of Narsaq.

17 minutes later, the engine chip detector light illuminated on the caution and warning panel, and a few seconds later, the engine low oil pressure light started illuminating.

The engine oil pressure gauge indicated zero, and the engine oil temperature was indicated as decreasing.

Shortly after, the pilot found indications of an engine power loss. The N1 (Gas Producer Turbine rotations per minute) indication was zero, and both the engine-out warning light and horn activated. However, the engine still produced power with a normal N2 (Power Turbine rotations per minute) indication.

The pilot identified an isolated, narrow sandy shore between steep cliffs along the fjord side and initiated a powered descent towards that area.

During the descent, the engine stopped, and the pilot performed an autorotation according to the Flight Manual (FM) Emergency Procedures.

Shortly before ditching, the pilot activated the emergency float system.

The pilot visually confirmed, based on what he could see from his position, that the floats had inflated.

The helicopter ditched a few meters (m) from the sandy shore identified by the pilot.

Upon ditching, with its main and tail rotor still turning, the helicopter slowly started rolling over onto its left side.

The helicopter rolled over 90° and came to rest with its LH fuselage side in contact with the seabed at a water depth of approximately 0.5 m.

Water entered the cabin and the cockpit.

During the evacuation, the pilot’s legs and feet got wet.

Until rescued, the pilot positioned himself on top of the Right Hand (RH) fuselage side.

The Emergency Locator Transmitter (ELT) automatically activated, causing the launch of a Search and Rescue (SAR) mission.

Approximately 1 hour and 15 minutes upon ELT activation, a SAR helicopter located and rescued the pilot.

Injuries to persons

|

Injuries |

Crew |

Passengers |

Others |

|

Fatal |

|

|

|

|

Serious |

|

|

|

|

Minor/None |

1 |

|

|

Damage to aircraft

Due to the sequence of events, the stay in seawater, and the salvage operation, the helicopter suffered substantial damage.

Figure 1. The helicopter lifted from the water onto the quay at Narsaq harbour.

Figure 2. The helicopter with damages on the quay at Narsaq harbour.

Other damage

None.

Personnel information

License and medical certificate

The pilot - male, 40 years - held a valid Danish Commercial Pilot Licence for Helicopters (CPL(H)).

The rating Bell 206 was valid until 30-6-2024.

The medical certificate (class 1) was valid until 19-7-2024.

Flying experience

|

|

Last 24 hours |

Last 90 days |

Total |

|

All types |

1 |

11 |

3,500 |

|

This type |

1 |

11 |

305 |

|

Landings this type |

2 |

80 |

1,000 |

Aircraft information

General information

|

Manufacturer: |

Bell Helicopter Textron Canada |

|

Type: |

206L-4 |

|

Serial number: |

52280 |

|

Airworthiness review certificate: |

Valid until 18-6-2024 |

|

Engine manufacturer: |

Rolls-Royce |

|

Engine type: |

250-C30P |

|

Engine serial number: |

CAE-895973 |

|

Engine hrs: |

5,910.5 |

|

Engine cycles: |

12,534 |

|

Maximum take-off mass (MTOM): |

4,450 pounds (lbs) |

|

Fuel on board at the time of the accident: |

485 lbs |

|

Aircraft total flight hours: |

12,713.16 hrs |

|

Latest maintenance: |

12-2-2024 |

Mass and balance

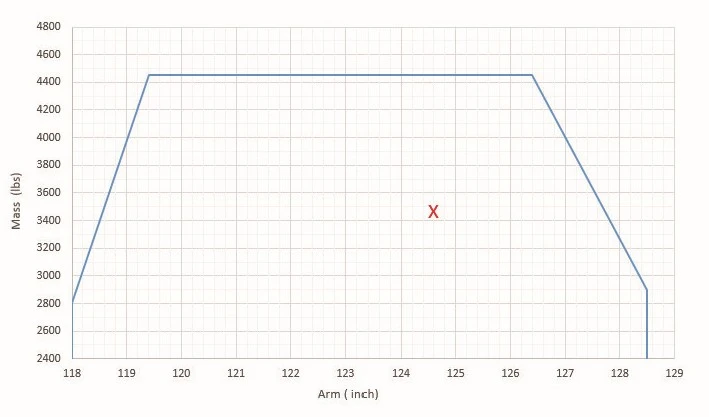

The AIB made a mass and balance calculation based on:

- the latest weighing report from April 2023

- pilot information about mass onboard

- pilot information about fuel onboard

- Bell Helicopter Maintenance Manual, Chapter 08

- Bell Helicopter 206L-4 FM

Longitudinal:

|

|

(lbs) |

Arm (inches) |

(lbs x inches) |

|

Empty mass: |

2,793.0 |

128.4 |

358,621.2 |

|

Pilot and passenger: |

175.0 |

65.0 |

11,375.0 |

|

Baggage: |

20.0 |

174.0 |

3,480.0 |

|

Fuel: |

485.0 |

122.4 |

59,364.0 |

|

Total mass at the time of the accident: |

3,473.0 |

124.6 |

432,840.2 |

Figure 3. Longitudinal mass and balance.

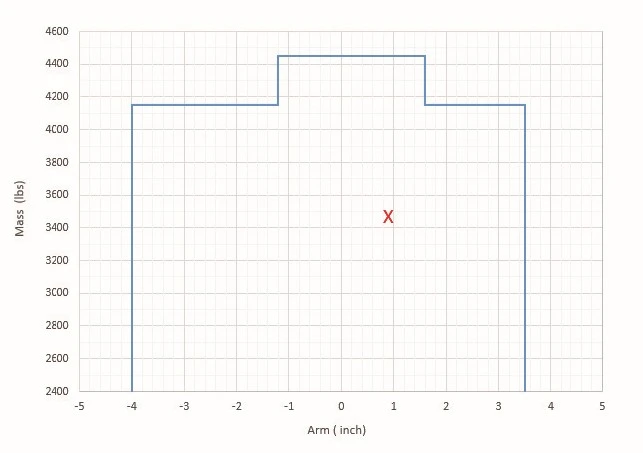

Lateral:

|

|

Mass (lbs) |

Arm (inches) |

Moment (lbs x inches) |

|

Empty mass: |

2,793.0 |

0.3 |

837.9 |

|

Pilot: |

175.0 |

14.0 |

2,450.0 |

|

Baggage: |

20.0 |

0.0 |

0.0 |

|

Fuel: |

485.0 |

0.0 |

0.0 |

|

Total mass at the time of the accident: |

3,473.0 |

0.9 |

3,287.9 |

Figure 4. Lateral mass and balance.

Maintenance history

|

16-11-2020: |

Replacement of the engine turbine rotor assembly. |

|

23-11-2021 until 5-2-2022: |

36-month float inspection performed without inflation of floats on the helicopter. |

|

30-10-2023 until 28-11-2023: |

50/100/150/300-hrs inspection performed. This inspection included:

The 18-month float system inspection was performed by replacing the six floats with inspected floats from the float manufacturer. |

|

9-2-2024: |

Replacement of the engine power turbine governor. |

|

11-2-2024: |

Engine chip detector light. Replacement of oil filter. |

|

11-2-2024 until 12-2-2024: |

24-month inspection performed. |

Engine general

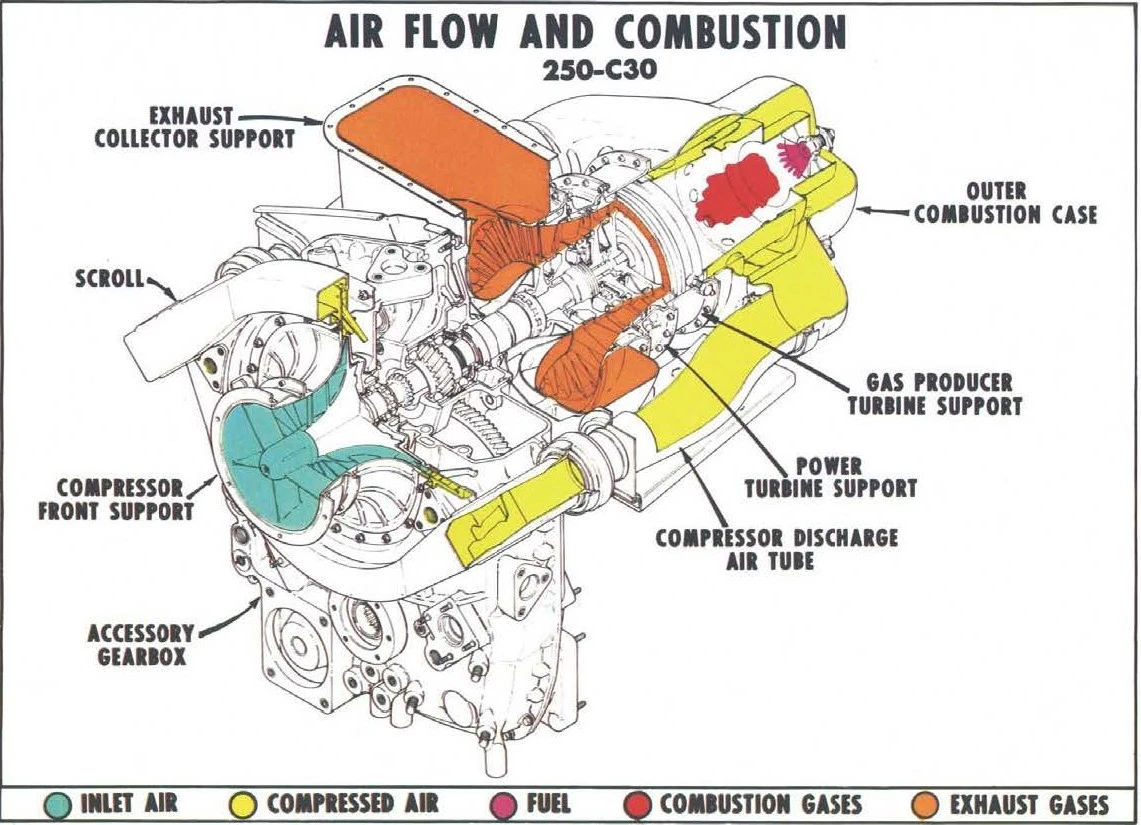

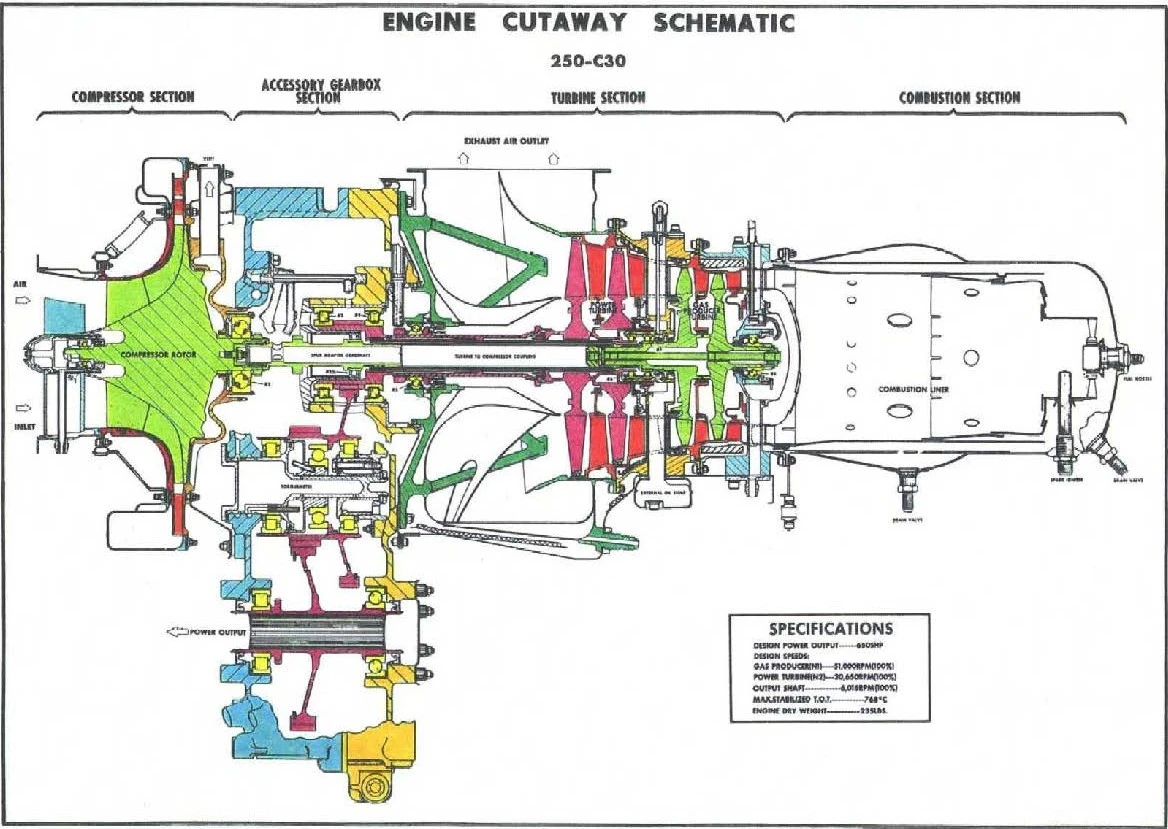

The engine consisted of:

- a single stage centrifugal flow compressor

- a single can-type combustor

- a turbine assembly, which incorporated a two-stage gas producer turbine, a two-stage power turbine, an exhaust collector, and an accessory gearbox

The accessory gearbox consisted of:

- a gas producer gear train

- a power turbine gear train

The two-stage gas producer turbine drove:

- the centrifugal flow compressor

- the fuel pump

- the fuel control unit

- the oil pump

- the N1(gas producer turbine rpm (rotations per minute)) tacho-generator

A common shaft drove the oil pump and the N1 tacho-generator.

The two-stage power turbine drove:

- the main rotor

- the tail rotor

- the N2 tacho-generator

- the turbine governor

See Appendix 1.

See Appendix 2.

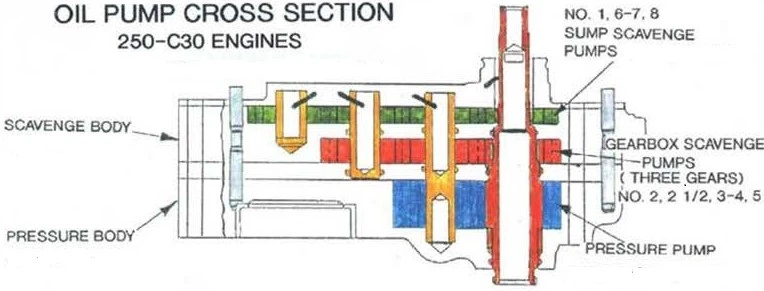

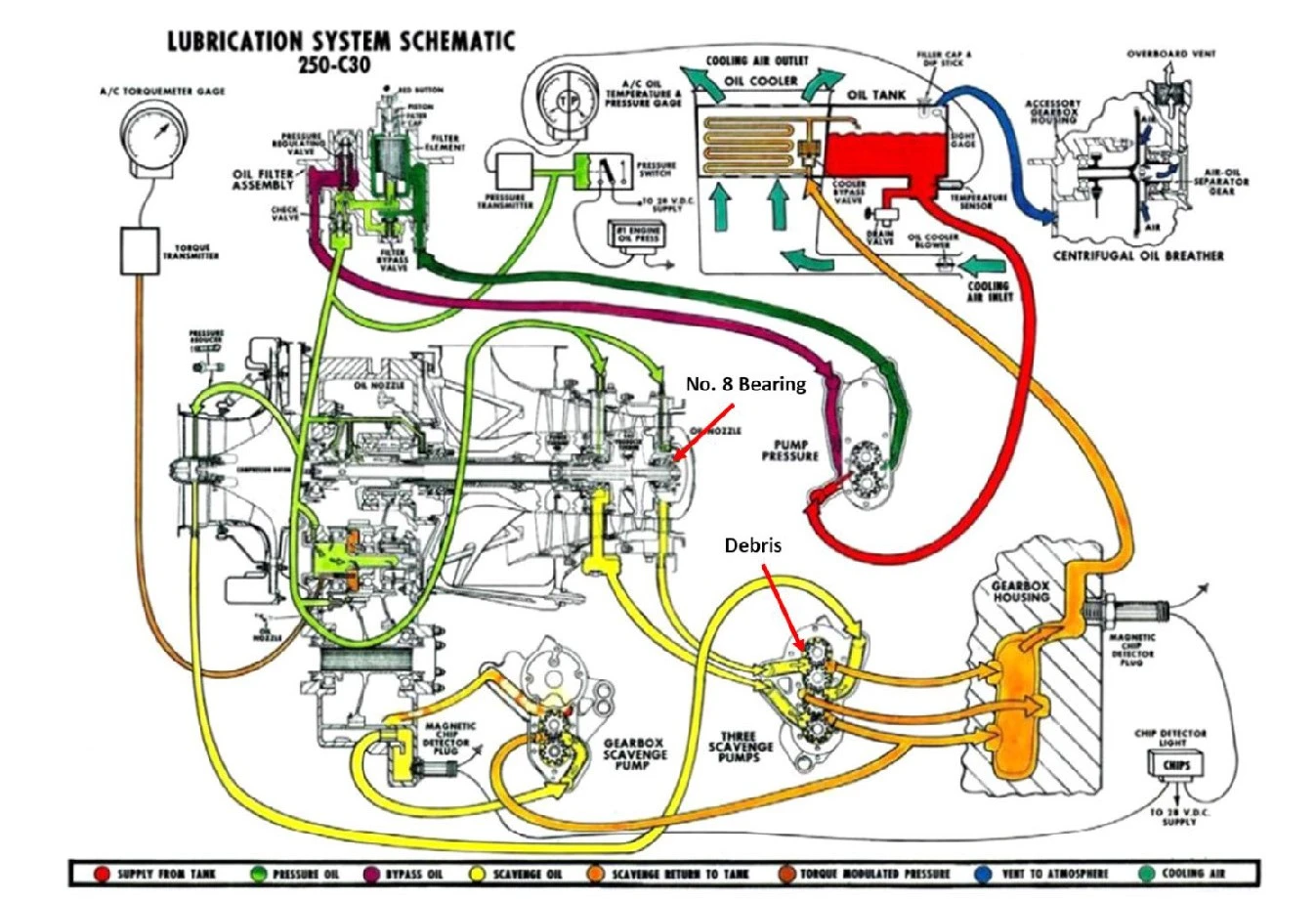

Engine oil system

The airframe manufacturer installed the engine oil tank on the top aft section of the fuselage. From the oil tank, a hoseline routed the oil by gravity to the inlet port at the oil pump pressure pump in the accessory gearbox.

The engine manufacturer routed pressurized oil from the oil pressure pump to the bearings of the engine compressor, the engine gas producer turbine, the engine power turbine, the accessory gearbox bearings and the gears for lubrication and cooling. The oil pump scavenge pumps in the accessory gearbox returned the heated oil to an oil cooler and back into the oil tank. See Appendix 3.

The engine manufacturer installed an oil filter just after the engine oil pressure pump. The airframe manufacturer installed a second oil filter after the oil scavenge pumps and before the return oil went into the oil cooler and the engine oil tank. The oil pump installed in the accessory gear box consisted of a pressure pump and scavenge pumps. A common shaft drove all pumps.

Figure 5. Oil pump cross section.

The engine manufacturer installed a total of two magnetic chip detectors in the engine oil system, one at the bottom of the accessory gearbox, and one on the engine accessory gearbox at the oil return line from the engine to the oil cooler and the engine oil tank.

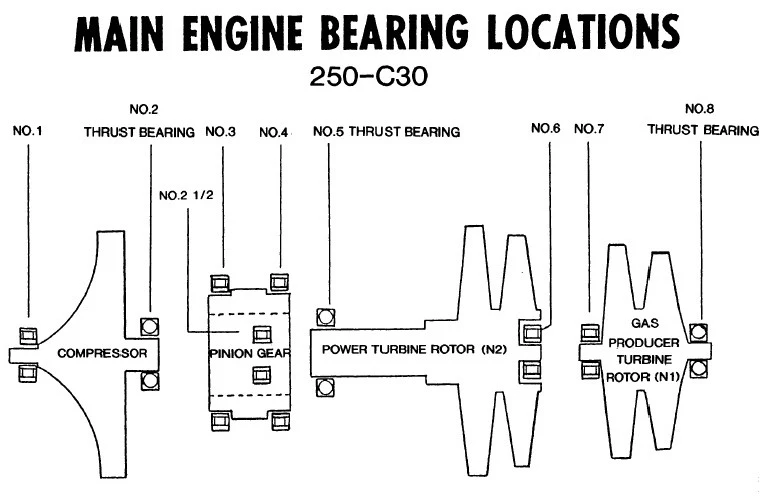

Engine bearing location

The engine manufacturer numbered the engine bearings as shown in the figure below.

Figure 6. Engine bearing locations and numbering.

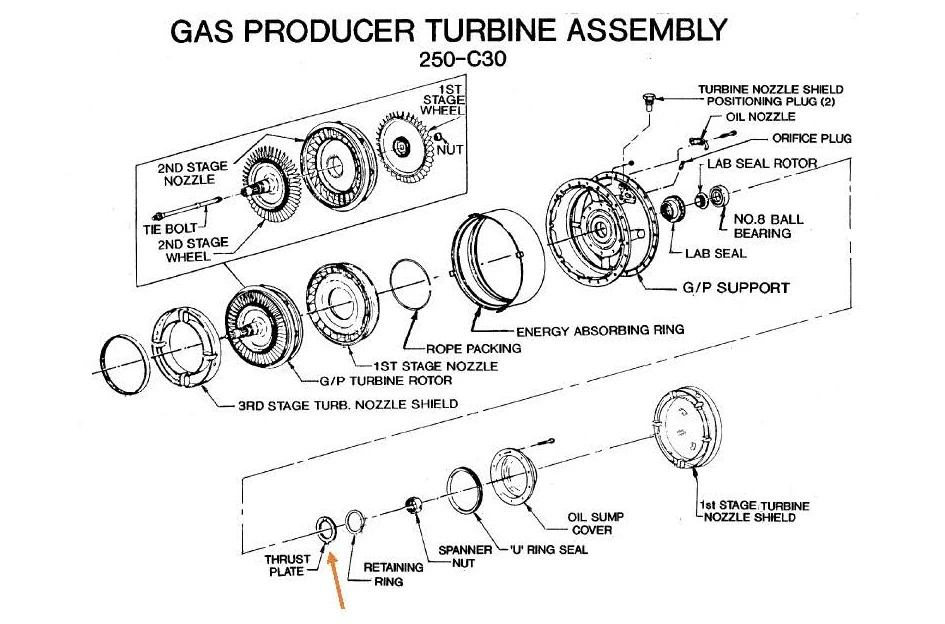

Gas Producer (G/P) turbine assembly

The Gas Producer Turbine assembly consisted of a G/P support in which the 1st stage nozzle and G/P turbine rotor were installed.

Bearing no. 7 and bearing no. 8 in the G/P support supported the G/P turbine rotor.

The engine manufacturer installed a thrust plate with an anti-rotation tab to prevent the outer race of bearing no. 8 from rotating. This tab fitted into slots of the G/P support and the outer race of bearing no. 8.

Figure 7. Location of the thrust plate in the gas producer turbine.

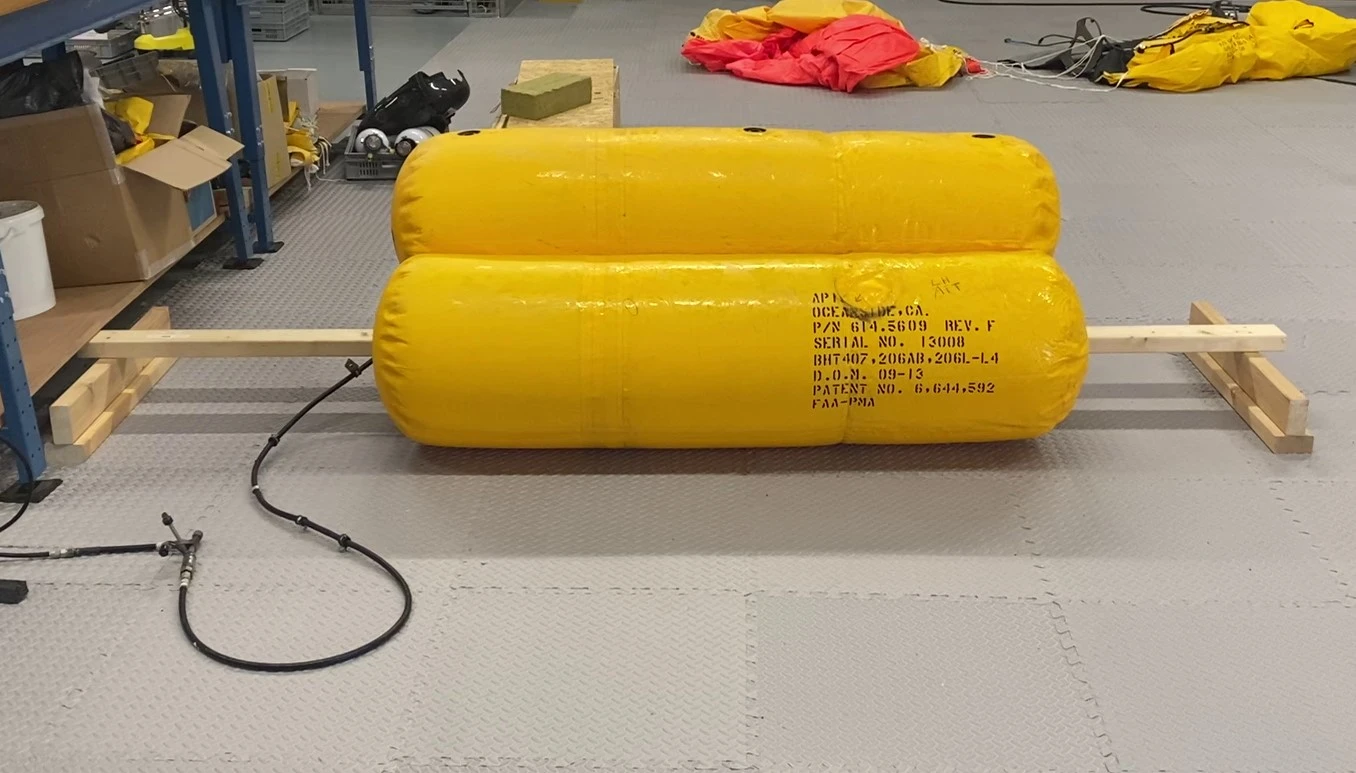

Emergency floats and liferafts

The installation of floats and liferafts provided ditching capability. The emergency float system was installed on the landing gear skid.

The emergency float system consisted of six floats: one forward (fwd), one mid and one aft on the LH and RH sides.

Each float consisted of gas holding chambers separated by internal bulkheads to minimize the loss of buoyancy in the event of a puncture.

Each separate chamber contained an inlet check valve for inflation, a combination topping valve for manual inflation, and a pressure relief valve to prevent overpressure.

Each float had interconnect hoses between the inlet valves.

Each of the mid floats also included a six-person liferaft.

The system included two pressurized gas reservoirs, installed on the belly of the helicopter. One reservoir supplied gas to the floats, and the other reservoir supplied gas to the liferafts.

On top of each of the reservoirs were discharge valves.

Hose-type supply lines connected the discharge valves to each of the floats and liferafts inlet valves.

Activating a lever handle on the cyclic stick in the cockpit activated the discharge valve of the gas reservoir through a cable, thus releasing the stored gas and inflating the floats.

The liferaft release mechanism handles were in three locations. One inside the cockpit on the centre console and two outside the cockpit on the landing gear skid fwd cross tube on the LH and RH sides.

Activating a lever handle activated the discharge valve of the gas reservoir through a cable, thus releasing the stored gas and inflating the liferafts.

Each release mechanism simultaneously inflated both liferafts.

Figure 8. The floats and liferafts packed and installed on the landing gear skid.

Figure 9. All floats and liferafts inflated

Figure 10. Gas reservoirs and hose lines on the belly of the helicopter.

Figure 11. Aft float with inlet valves and interconnect hoses. Fwd and mid floats only had two inlet valves.

Meteorological information

Terminal Aerodrome Forecast (TAF)

|

TAF BGBW: |

281405Z 2815/2821 23010KT 9999 BKN085 BECMG 2815/2818 FEW050 BECMG 2818/2821 18005KT= |

The accident site was located 20.5 nm southwest of BGBW.

Aviation Routine Weather Weather Report (METAR)

|

METAR BGBW: |

281650Z 23009KT 190V250 9999 FEW038 SCT070 BKN082 M05/M14 Q1001= |

|

METAR BGBW: |

281550Z 25006KT 9999 FEW035 SCT063 BKN082 M05/M14 Q1001 RMK 2SC 4AC 6AC= |

After 12:20 hrs, BGJH issued neither METAR nor TAF.

BGJH recorded the following actual wind, temperature, dewpoint and QNH:

|

Time |

Wind |

Temperature |

Dewpoint |

QNH |

|

15:50: |

283º and 12 knots (kt), with gusts up to 17 kt |

-5.1º Celsius (C) |

-13.4 ° C

|

1002 hectopascal (hPa) |

|

16:00: |

280º and 14 kt, with gusts up to 19 kt |

-5.2º C |

-14.0º C |

1002 hPa |

|

16:10: |

282° and 16 kt, with gusts up to 22 kt |

-5.3° C |

-13,8° C |

1002 hPa |

Narsaq (BGNS) issued neither METAR nor TAF.

BGNS was located 23.5 nm southwest of BGBW.

BGNS recorded the following actual wind, temperature, dewpoint and QNH:

|

Time |

Wind |

Temperature |

Dewpoint |

QNH |

|

16:00 |

266º and 18 kt, with gusts up to 20 kt |

-5.1º C |

-10.8º C |

1001 hPa |

|

17:00 |

267°and 21 kt, with gusts up to 25 kt |

-5.1º C |

-10.4°C |

1002 hPa |

Aftercast

For BGBW and the area near BGNS on 28-11-2024 at 16:15 hrs.

|

General: |

A low north-east of Cape Farewell moved north-east, causing a relatively strong westerly flow of cold and unstable air with showers of snow over the southern part of Greenland, especially along the coasts. |

|

Weather and visibility: |

In BGBW, no significant weather, except a risk of drifting or blowing snow. In BGNS and BGJH, there was most likely drifting/blowing snow as well as intermittent light/moderate showers of snow, especially in the outer fjords, risk of showers. In connection with showers and blowing snow, the visibility was between 700 m and 5-kilometres (km), depending on the intensity of the showers. There was risk of lower visibility, if showers were coincident with blowing snow. The visibility was more than 10 km. |

|

Clouds and icing: |

BGBW: broken (bkn), locally scattered (sct), altocumulus (ac) / altostratus (as) at 5,000 ft to 8,000 ft. Below, few stratocumulus (sc)/cumulus (cu) at 3,000 to 5,000 ft. BGNS and BGJH: sct/bkn sc/cu/ towering cumulus (tcu)/ac base 2,000 - 5,000 ft. In connection with light/moderate showers of snow, cloud base/vertical visibility down to 400 to 2,000ft. Freezing level at the surface. Light to moderate icing in clouds, and in connection with tcu severe icing. |

|

Surface wind: |

In BGBW: west and south-west, 220-250°, 5-15 kt. In BGNS and BGJH: west and north-west 220-290°, 10-22 kt, with gusts up to 25 kt. |

|

Wind and temperature in 2,000 ft: |

Westerly, 15-25 kt, strongest in the south. |

|

Turbulence and windshear: |

Light to moderate turbulence. In tcu, the risk was severe. Just east of the area, there was a risk of widespread moderate turbulence. |

Communication

The pilot was in radio contact with Nuuk Flight Information Centre (FIC).

During the sequence of events, the pilot did not issue a Mayday call.

Flight recorders

There were no onboard flight recorders.

An installation of onboard flight recorders on this type of helicopter was not a legal requirement.

Wreckage and impact information

When the SAR helicopter arrived at the accident site, OY-HIO laid on its LH side, partially submerged in the water close to the shore.

Apart from the LH aft float, all floats were inflated.

Both liferafts were inflated.

Figure 12. The helicopter laid in the water on its LH side.

Figure 13. The helicopter on its LH side close to the shore.

Figure 14. Location of the accident site at Tunulliarfik Fjord.

Fire

There was no fire.

Survival aspects

General

The pilot wore ordinary clothing.

The pilot’s feet and legs got wet during the evacuation.

The pilot used the shoulder and lap seat belt harnesses.

Inflation of the yellow floats and liferafts improved the visibility of the helicopter from the air.

The onboard ELT was not under water.

The pilot wore ordinary clothing.

The pilot’s feet and legs got wet during the evacuation.

The pilot used the shoulder and lap seat belt harnesses.

Inflation of the yellow floats and liferafts improved the visibility of the helicopter from the air.

The onboard ELT was not under water.

ELT

Model ME406 - Part No: 453-6603 Rev: D.

The ME406 was a type AF (Automatic Fixed) beacon, transmitting on 121.5 and 406 mega -hertz (MHz).

The location of the ELT was in the cockpit on the LH side of the pedestal fwd and below the instrument panel.

The ELT was armed and did automatically activate during the sequence of events.

Personal Locator Beacon (PLB)

Each liferaft contained a PLB and a survival kit.

The sequence of events did not trigger activation of the PLBs.

Search and rescue

At 16:16 hrs, the onboard ELT automatically activated the International Satellite System for Search and Rescue Services (COSPAS- SARSAT), relaying the distress signal to Nuuk FIC.

The pilot audibly noted the activation of the ELT.

Via Joint Arctic Command, Nuuk FIC scrambled a SAR helicopter from BGBW to the accident site.

Approximately 20 minutes after the accident occurred, Nuuk FIC directed a helicopter from the same operator from BGBW to the accident site.

The pilot of the company helicopter had difficulties locating the accident site, and due to low fuel reserves, had to stop the search after a short period of time.

At 17:17 hrs, the SAR helicopter started the search and located the accident site at 17:29 hrs.

At the time of rescue, the pilot was conscious but had a low body temperature.

The SAR helicopter flew the pilot to the hospital in the city of Qaqortoq.

The following day, the hospital released the pilot.

Parallel to the rescue operation by air, the local police in Narsaq started a SAR operation by boat from Narsaq harbour.

Onboard the boat was a doctor, a nurse, a police officer, and three fire fighters.

At 18:53 hrs, they located the accident site.

AIB technical safety investigation

Preliminary engine inspection

At a warehouse in Narsaq, a thorough technical engine inspection, with the engine installed on the helicopter revealed the following abnormalities:

- The compressor impeller could not be turned.

- Removal of the chip detector at the bottom of the engine accessory gearbox and at the engine accessory gearbox oil outlet to the oil cooler and engine oil tank revealed ferrous material.

- The engine oil hoselines from the engine accessory gearbox to the oil cooler/the engine oil tank and from the engine oil tank to the engine accessory gearbox did not contain any oil. However, the engine oil tank oil level did not indicate that oil was be added.

- The engine exhaust pipe had engine oil stains.

- Upon removal of the engine accessory gearbox chip detector at the bottom of the engine accessory gearbox, no engine oil came out.

- The first-stage turbine wheel had blade tip damages.

- A greenish powdery substance could be seen inside the accessory gearbox.

Removal of the complete engine from the helicopter for further technical inspections gave no rise to remarks.

Engine tear down inspection

An approved engine repair and overhaul facility performed a teardown inspection in cooperation with and under supervision of Rolls-Royce and the AIB.

Figure 15. The engine at the engine repair and overhaul facility.

Inspections with remarks:

- The outer combustion case, the inner combustion chamber and the fuel nozzle had no damages. However, the two latter displayed black soot.

Inspections without remarks:

- The external accessories on the engine accessory gearbox (rotor brake, freewheel unit, fuel control unit, fuel pump, power turbine governor) revealed no obvious abnormalities other than saltwater intrusion and corrosion.

- A flow check for obstructions with low pressure oil of the engine oil supply and scavenge lines for the engine bearings revealed no abnormalities. There were no blockages of the engine oil lines.

- The engine oil line filter screen at the T-fitting for bearing no. 6 and 7 was clean.

Turbine inspection:

- The drive shafts from the gas producer turbine and from the free turbine could not be turned.

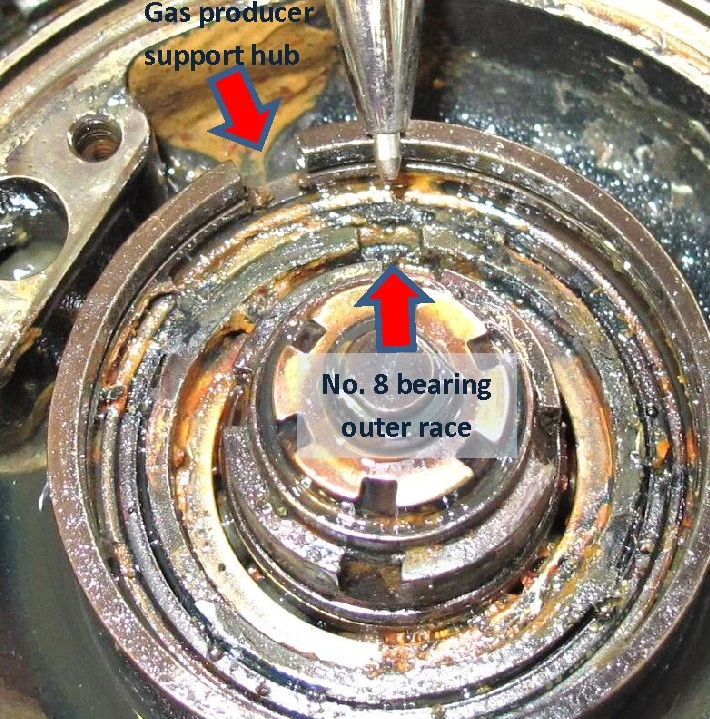

- Upon removal of the bearing no. 8 oil sump cover, the thrust plate at bearing no. 8 lacked an anti-rotation tab.

- The outer race slot of bearing no. 8 had turned approximately 10° clockwise in relation to the gas producer support hub slot.

Figure 16. Bearing no. 8 outer race slot did not line up with the gas producer support hub slot.

- Upon installation of the thrust plate, the outer part of the anti-rotation tab fitted into the slot at the gas producer support hub.

- The inner part of the thrust plate anti-rotation tab fitted into the bearing no. 8 outer race slot.

- The anti-rotation tab, per design, prevented the outer race of the bearing from rotating.

- The no. 8 bearing sump had a film of oil. The bearing looked normal but could not rotate.

- The blade tips of the first-stage turbine wheel were damaged.

- There were no damages to the second-stage turbine wheel, the nozzles or the gas producer hub.

- The power turbine support hub, which contained bearings no. 6 and 7, was corroded.

- Bearing no. 6 looked normal with intact rollers, but could not rotate.

- Bearing no. 7 looked normal, and the rollers appeared undamaged.

- An inspection of the third- and fourth-stage turbine wheels and nozzles gave no rise to remarks.

- Bearing no. 5 looked normal but could not rotate.

Compressor inspection:

- The compressor could not be turned.

- Bearing no. 2 was damaged.

- The impeller blade leading edges showed heavy material transfer from contact with the impeller shroud.

- Bearing no. 1 looked normal.

Figure 20. Damage to the impeller blade leading edges.

Figure 21. Impeller shroud rub marks caused by contact with the impeller blades.

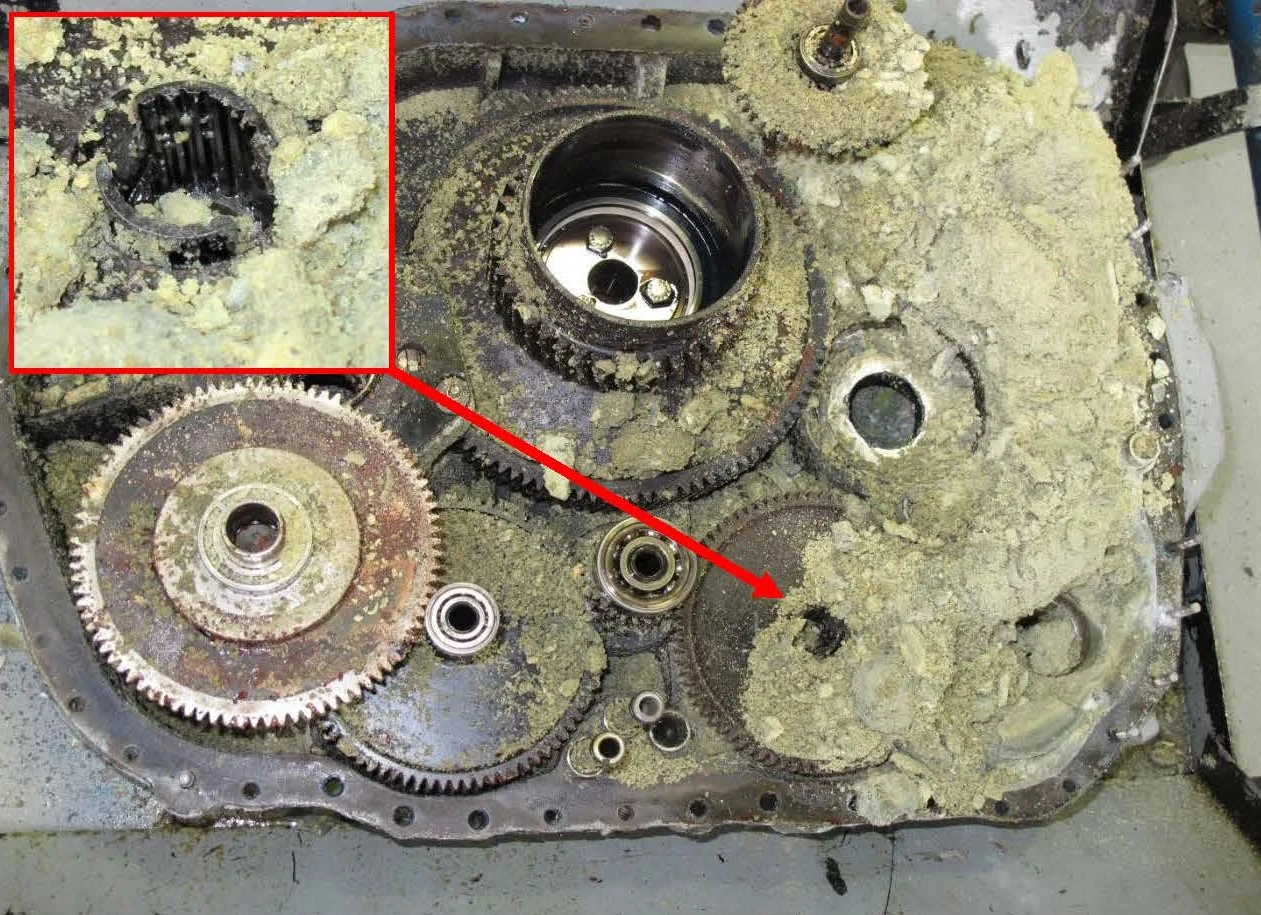

Accessory gearbox inspection:

- The gas producer turbine and the power turbine input geartrains could not be rotated.

- The accessory gearbox was full of a greenish powdery substance, consistent with deterioration of the accessory gearbox magnesium housing after exposure to salt water.

- Bearings no. 2 ½, 3 and 4 were normal in appearance but could not rotate.

- A drive shaft coupling from the fuel control gearshaft to the oil pump gearshaft was fractured.

Figure 22. One half of the split opened accessory gearbox with a greenish powdery substance and a fractured drive shaft coupling to the oil pump gearshaft.

Figure 23. Opposite half of the accessory gearbox with the fractured drive shaft coupling to the oil pump input gearshaft.

- The oil pump input gearshaft could not be rotated. The oil pump was disassembled.

- The oil pump shaft and the pressure and scavenge gear teeth were intact.

- Within the scavenge cavity of the pump scavenging oil from the gas and power turbine bearings, a piece of debris lodged between the gear and the pump housing prevented rotation of the gear.

..jpg)

Figure 24. Engine oil scavenge pump disassembled with a piece of debris (gear had been displaced to show the piece of debris).

The engine manufacturer forwarded the thrust plate from the engine, without the anti-rotation tab and the piece of debris found in the scavenge pump, to a laboratory for further analysis.

The laboratory concluded that the chemistry and morphology of the piece of debris was consistent with the anti-rotation tab of the thrust plate at bearing no. 8.

The anti-rotation tab of the thrust plate was brazed on the thrust plate ring.

The laboratory discovered that the brazing of the lost anti-rotation tab to the thrust plate ring only had a coverage of 30%, which did not meet the specification requirement of minimal 80% coverage.

Preliminary float inspection

At a warehouse in Narsaq a thorough technical float inspection, with the floats installed on the helicopter, revealed the following findings:

- The float activation handle on the cyclic stick had been activated.

- All floats apart from the LH aft float had been inflated.

- All float gas supply lines and their connections from the gas reservoirs bottle to each float inlet valves were visually inspected without remarks, and all connections were tightened.

- Float and liferaft gas reservoir pressure gauges indicated zero pounds per square inch (psi), and the discharge valves were inspected without remarks.

- The RH fwd, mid, and aft float inlet valves and inlet valves interconnect hoses were inspected without remarks, and all connections were tightened.

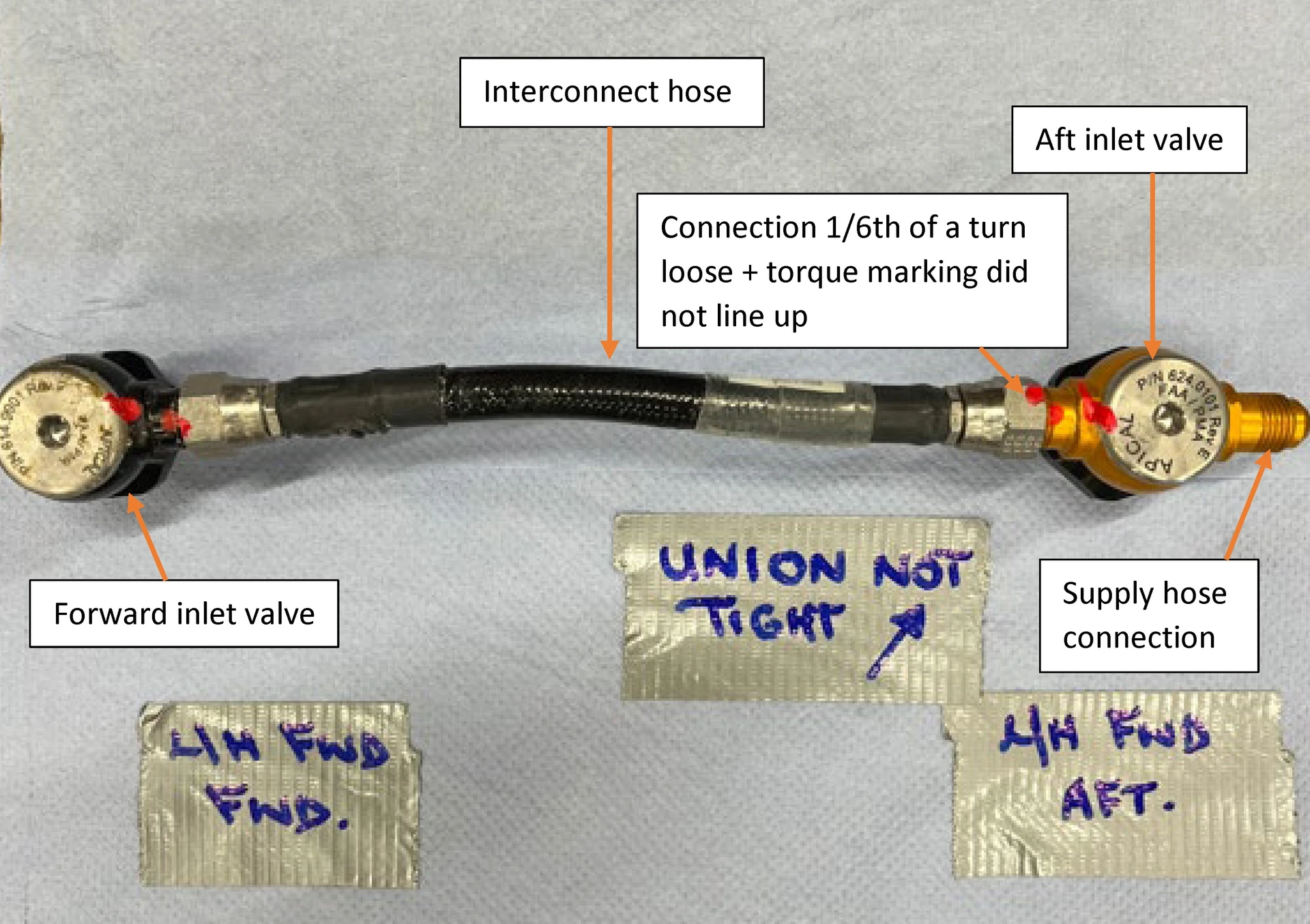

- The LH fwd float inlet valves, including the interconnect hose, were inspected. The interconnect hose connection to the aft inlet valve were not properly tightened.

- The connection was one-sixth (1/6th) of a turn loose, and torque witness marks did not line up. Upon removal of the interconnect hose from the inlet valve, several drops of water came out.

- There was salt debris in the aft inlet valve.

Figure 25. LH fwd float interconnect hose connection to the aft inlet valve was not tightened.

Figure 26. Salt debris in the LH fwd float aft inlet valve.

- LH mid float inlet valves, including inlet valve interconnect hoses, were inspected without remarks, and all connections were tightened.

- The LH aft float, uninflated, was inspected including its gas supply line hose, without remarks. However, the supply hose was not straight and had bends.

Figure 27. Bends on the supply line to the LH aft float.

- The liferaft release handle at the pedestal in the cockpit was partly pulled.

- The external RH side liferaft release handle was fully pulled.

Inspection and testing of the LH aft float

The float manufacturer service centre performed all inspections and testing in cooperation with and under supervision of the AIB.

- A visual inspection of the float assembly, including the packing, gave no rise to remarks.

- A visual inspection of the float inlet valves, including inlet valve interconnect hoses and supply line hose, gave no rise to remarks.

- All hose connections to the inlet valves were found tightened.

- All inlet valves were fully functional without any blockages.

- An internal check for blockages of all inlet valves, interconnect hoses, and supply hose, including port fitting, revealed no blockages.

- Approximately 1 millilitre (ml) of water came out of the aft inlet valve interconnect hose upon removal from the middle inlet valve.

Upon reinstallation and connection of all float parts, a float inflation was successful.

%20of%20water%20came%20out,%20when%20the%20inlet%20valve%20interconnect%20hose%20at%20the%20LH%20aft%20float%20was%20disconnected..jpg)

Figure 28. Approximately 1 millilitre (ml) of water came out when the inlet valve interconnect hose at the LH aft float was disconnected.

Figure 29. Fully inflated LH aft float during test.

Testing of the complete float system

The float manufacturer service centre performed the tests in close cooperation with the AIB.

The service centre received all parts that made up the complete float system of OY-HIO, except the supply hose to the RH aft float. For the following tests, the service centre used a serviceable supply hose similar to that of the RH aft float.

Upon receipt, the RH aft float from OY-HIO was punctured. For the following tests, the service centre used a similar, serviceable RH aft float.

The service centre performed two freezing tests of the complete float system to determine how much water was needed in the supply hose to the LH aft float to prevent it from inflating when frozen.

Prior to testing, the service centre loosened the LH fwd float inlet valve interconnect hose connection to the aft inlet valve by one sixth (1/6th) of a turn from the tightened position.

Freezing test no. 1:

- They injected 15 ml of water into the LH aft float supply hose while the hose was slightly bent in a bucket.

- They stored the complete float system, including the supply hose, in a -21 °C freezing chamber for 24 hours.

- Upon removal of the complete float system from the freezing chamber, and upon removal of the LH aft supply hose from the bucket, they connected it to the complete float system.

- They activated the complete float system and all floats, except the LH aft float, inflated.

Figure 30. Test with 15 ml of frozen water in the LH supply hose. The LH aft float did not inflate.

Freezing test no. 2:

- The service centre performed a test similar to freezing test no. 1. However, they only injected 7 ml of water into the LH aft float supply hose.

- They activated the complete float system, and all floats inflated. However, the forward chamber of the LH aft float did not inflate, because of ice from the supply hose froze up the fwd inlet valve.

Figure 31. Second test with 7 ml of water in the LH supply hose. The LH aft float partially inflated.

Figure 32. LH aft float fwd inlet valve froze up by ice from the supply hose.

Water ingress test of the LH fwd float interconnect hose connection:

- The service centre loosened the LH fwd float inlet valve interconnect hose connection to the aft inlet valve one-sixth (1/6th) of a turn from the tightened position.

- They submerged the LH fwd float, with the loose interconnect hose connection at the aft inlet valve with the connected supply hose, into water for 18 hours.

- Upon completion of the test, they disassembled the inlet valves, interconnect hoses, and supply hose.

- The test revealed no ingress water.

Water ingress test of the remaining floats:

- The service centre submerged the remaining floats with interconnect hoses, inlet valves, and supply hoses into a water tank for approximately 18 hours before checking for any water ingress.

- Upon completion of the test, they disassembled the inlet valves, interconnect hoses, and supply hoses.

- The test revealed no ingress water.

Float system inspection requirement

The float system maintenance requirement included inspections every 18 and 36 months according to the float manufacturer’s “Instruction for Continued Airworthiness” document.

For extracts of the revision AG of the float manufacturer’s “Instruction for Continued Airworthiness” document, see Appendix 4.

Analysis

General

The pilot was properly licensed.

The helicopter was airworthy.

The helicopter mass and balance had no influence on the sequence of events.

Due to the activated ELT, daylight, and good visibility, the launched SAR helicopter quickly located the accident site and rescued the pilot.

The SAR operation was effective and positively impacted the chance of survival in a hostile area.

The pilot wore ordinary clothing, and upon ditching his feet and legs got wet during the evacuation. The pilot sat outside in -5 °C for 1 hour and 15 minutes. Though not legally required, in the opinion of the AIB, a survival suit in a hostile area would most likely have reduced the risk of hypothermia.

Loss of engine power

The AIB concludes that the engine power loss was most likely caused by the following sequence of events within the engine:

- The bearing no. 8 thrust plate anti-rotation tab separated from the thrust plate ring and travelled with the engine oil to the scavenge side of the oil pump. See Appendix 3.

- Debris from the anti-rotation tab triggered the engine chip detector light.

- Parts of the anti-rotation tab got trapped between a scavenge pump gear and the wall of the scavenge pump housing.

- The oil pressure pump and scavenge pump stopped.

- The drive shaft coupling from the fuel control gearshaft to the oil pump gearshaft fractured.

- There was no oil pressure and no N1 indication. The gas producer turbine and power turbine were still running.

- A stopped scavenge pump resulted in no warm engine oil flowing from the engine to the airframe oil tank, where the engine oil temperature was measured. Hence the indicated temperature of the engine oil in the engine oil tank started to decrease.

- Bearing no. 2, supporting the compressor impeller, started to degrade due to lack of lubrication caused by the stopped engine oil pressure pump.

- Further degradation of bearing no. 2 led to a sudden hard contact between the impeller and the shroud. The impeller stopped turning, which led to the loss of engine power.

LH aft float did not inflate

During the latest required three-year inspection of the float system, the operator did not inflate the floats of the helicopter as required by the float manufacturer.

Scheduled float inflation on the helicopter, as required by the float manufacturer, would likely have reduced the risk of (water) contamination in the supply lines to the floats.

On the accident day, from start in the morning until the accident occurred, the helicopter operated in temperatures between -5° C and -10° C.

The supply line/hose to the LH aft float was not straight but had some light bends, allowing water to be trapped.

The AIB did not succeed in determining why water was present in the float supply lines.

The amount of water found in the interconnect hose at the LH aft float was less than the amount found by testing to prevent the LH aft float from inflating when frozen.

For that reason, the AIB did not unequivocally determine the cause of the LH aft float not inflating.

However, taking into consideration the combination of the actual operational outside air temperature and a lightly bended LH aft float supply line/hose, the AIB finds it likely that the LH aft float did not inflate due to frozen water being present in the supply line/hose to the LH aft float.

Conclusions

En route, liberation of an anti-rotation tab from a thrust plate at engine bearing no. 8 resulted in a total engine power loss and, consequently, an autorotation over water.

Prior to ditching, the pilot activated the float system. However, the LH aft float did not inflate, resulting in the helicopter rolling over onto its left side upon ditching.

The likely reason for the LH aft float not inflating was frozen water in the supply line to the LH aft float.

Safety actions

Mitigating safety action by the engine manufacturer

In December 2022, the engine manufacture issued a Commercial Engine Bulletin CEB-72-3309, covering the issue of the liberation of the retaining feature (anti-rotation tab) of the thrust plate and the installation of a new improved thrust plate.

The new, improved trust plate was manufactured in one piece instead of two pieces (ring + anti-rotation tab) brazed together.

At the time of the accident, the service bulletin had not been completed on the engine of OY-HIO.

See Appendix 5.

Upon the accident of OY-HIO and the subsequent safety investigation, in October 2024, the engine manufacturer issued a revision 1 to the Commercial Engine Bulletin CEB-72-3309.

See Appendix 6.

Mitigating safety action by the float manufacturer

At the time of the accident, the float manufacturer’s “Instruction for Continued Airworthiness” document did not contain specific information on how to ensure float supply lines being clean and free of blockages/water.

The float manufacturer will update the “Instruction for Continued Airworthiness” document with instructions on how to verify that float supply lines are free of blockages/water before installation of the floats.

Appendices

Appendix 1

Return to Engine general.

Appendix 2

Return to Engine general.

Appendix 3

Return to Engine oil system or Loss of engine power

Appendix 4

Appendix 5

Appendix 6

Contact the Accident Investigation Board

If you have any questions about this publication, please feel free to contact us.

.jpg)

.jpg)

.jpg?width=1920)

.jpg)

.jpg?width=1920)

.jpg)

.jpg)